Gold has been a symbol of wealth and prosperity for centuries, and its value continues to hold strong in the modern world. The process of refining gold, transforming it from raw ore to pure bullion, is a complex and fascinating journey that involves several stages of extraction, purification, and casting. This article delves into the intricate process of refining gold, exploring the methods and technologies used to achieve the highest levels of purity and quality.

Understanding Gold Ore and Its Extraction

Gold ore is the raw material from which gold is extracted. It is found in various geological formations, often mixed with other minerals and metals. The first step in the refining process is to extract the gold from the ore. This is typically done through mining, which can be conducted using several methods, including open-pit mining, underground mining, and placer mining.

Once the ore is extracted, it undergoes a series of processes to separate the gold from other materials. One common method is the use of cyanide leaching, where the ore is treated with a cyanide solution that dissolves the gold, allowing it to be separated from the rest of the material. Another method is the use of gravity separation, where the heavier gold particles are separated from lighter materials using water and gravity.

After the initial extraction, the gold is still in an impure form, often mixed with other metals such as silver, copper, and zinc. To achieve a higher level of purity, the gold must undergo further refining processes.

The Refining Process: Purifying Gold

The refining process is crucial in transforming impure gold into high-quality bullion. There are several methods used to refine gold, each with its own advantages and limitations. The most common methods include the Miller process, the Wohlwill process, and the use of aqua regia.

The Miller Process

The Miller process is one of the fastest and most cost-effective methods of refining gold. It involves blowing a stream of chlorine gas through the molten gold, which reacts with the impurities to form chlorides that can be easily removed. This process can achieve a purity level of up to 99.5%, making it suitable for many industrial applications.

The Wohlwill Process

The Wohlwill process is a more advanced method of refining gold, capable of achieving purity levels of up to 99.999%. It involves the use of an electrolytic cell, where the impure gold is dissolved in a solution and then deposited onto a cathode as pure gold. This method is more time-consuming and expensive than the Miller process but results in a higher level of purity.

Refining with Aqua Regia

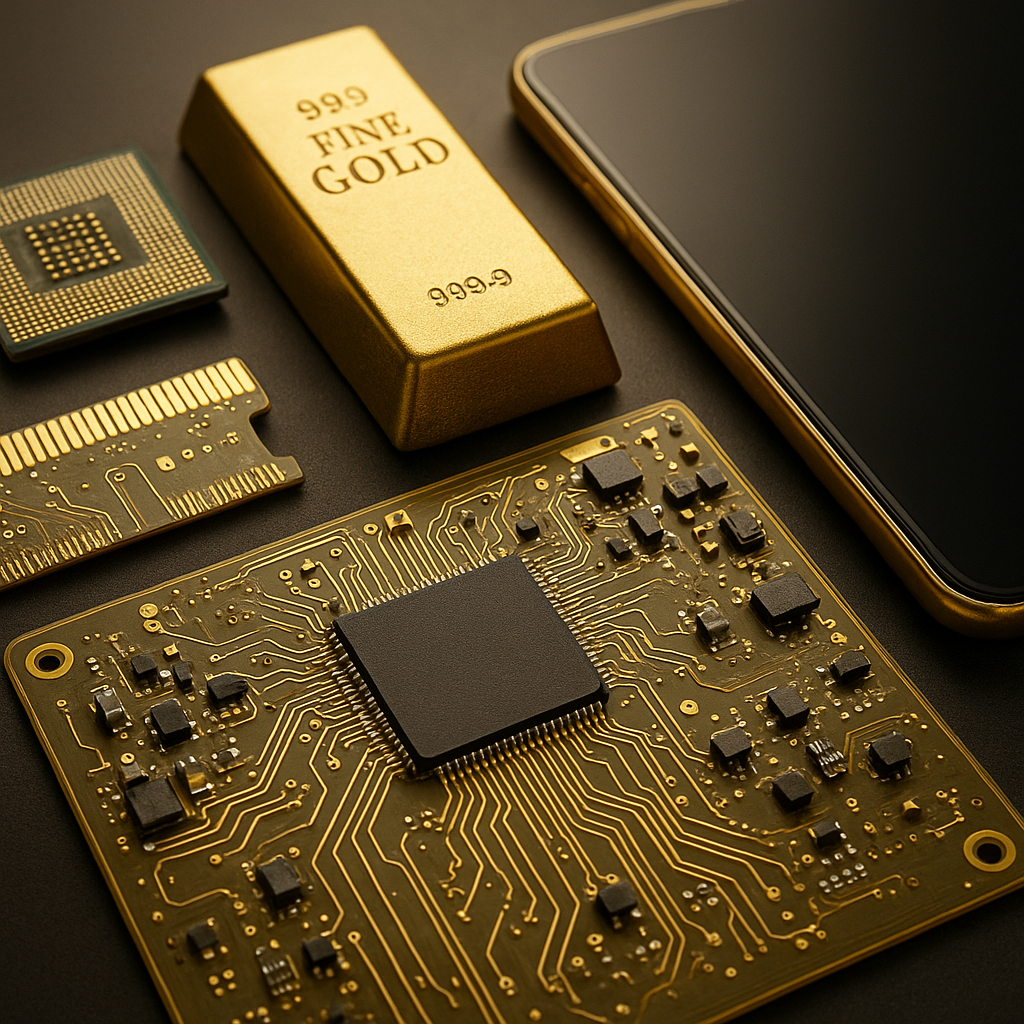

Aqua regia, a mixture of nitric acid and hydrochloric acid, is another method used to refine gold. This process involves dissolving the impure gold in the acid solution, which separates the gold from other metals. The gold is then precipitated out of the solution and further purified through a series of chemical reactions. This method is often used for refining small quantities of gold or for recovering gold from electronic waste.

Casting and Forming Gold Bullion

Once the gold has been refined to the desired level of purity, it is ready to be cast into bullion. This involves melting the purified gold and pouring it into molds to form bars or ingots. The casting process must be carefully controlled to ensure that the gold cools evenly and forms a solid, uniform structure.

After casting, the gold bullion is often stamped with information such as its weight, purity, and the refiner’s mark. This provides assurance to buyers and investors that the gold meets the required standards of quality and authenticity.

The Role of Technology in Gold Refining

Advancements in technology have played a significant role in improving the efficiency and effectiveness of the gold refining process. Modern refineries use state-of-the-art equipment and techniques to achieve higher levels of purity and reduce environmental impact.

Automation and computer-controlled systems have streamlined many aspects of the refining process, allowing for greater precision and consistency. Additionally, new methods of waste management and recycling have been developed to minimize the environmental footprint of gold refining operations.

Conclusion: The Journey from Ore to Bullion

The process of refining gold from ore to bullion is a complex and intricate journey that requires a deep understanding of chemistry, metallurgy, and engineering. Each step in the process, from extraction to purification to casting, plays a crucial role in transforming raw materials into valuable assets.

As technology continues to advance, the gold refining industry will likely see further improvements in efficiency, sustainability, and quality. This ongoing evolution ensures that gold remains a vital and sought-after commodity in the global market, symbolizing wealth and prosperity for generations to come.